Resources

- All

- Blog

- Case Studies

- E-Book

- News

2025: A Year to Prioritize Workplace Safety

SIC and FMS for Room and Pillar Operations

The Art of Short-Term Scheduling in Mine Operations

SIC and FMS for Cut-and-Fill Operations

MSHA Doesn’t Just Write Tickets

Increasing Mining Production through Workflow Optimization

Reducing Downtime in Mining with Predictive Maintenance

How Mining Automation Is Redefining Operational Safety

Leveraging Real-Time Data for Accurate Decision-Making in Mining

Short Interval Control and FMS for Block Caving Operations

Dynamic Dispatch in Fleet Management Systems

Pre-Shift Inspections: A Key Step in Mining Safety and Efficiency

Customized Alerts and Notifications: A Game Changer for Mining Operations

How Real-Time Monitoring Prevents Costly Errors in Mining

Understanding Efficiency in Mining Operations: Breaking Down Key Metrics

Improve Overall Equipment Effectiveness using GroundHog Mine Digitization Solution

Improving Operational Efficiency at Mines Understanding Overall Equipment Effectiveness.

GroundHog ROM Loader Solution

Diagnostic Port Pin-outs on Caterpillar Equipment, Caterpillar VIMS, and OEM Agreements

Requesting Specific PGNs and Diagnostic Trouble Codes

Practical Aspects of Reading Telemetry Data from Diagnostic Ports.

Importance of telemetry data for maintenance teams

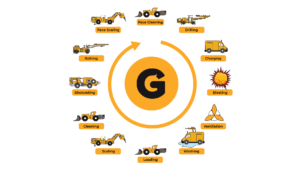

Short Interval Control with GroundHog

Ore Blending and Grade Control at ROM Stockpile

Essential Guide to MSHA-Compliant Mobile Equipment Training for Safe Mining Operations

Optimizing Ore Control and Reducing Dilution with GroundHog’s Precision Solutions

Harnessing High-Precision GPS for Enhanced Ore Quality Control in Open-Pit Mines

Unlocking Efficiency: Ore Dilution and Quality Control in Open-Pit Mines

Long hole stoping with SIC

A Guide to Harnessing CAT Telemetry Data

How to read Telemetry Data from Normet Equipment?

SAP Counter Reading Automation e-Book

Risk Assessment in Mining: Staying Vigilant to Minimize Hazards and Accidents

GroundHog Unveils Smart Routing for Autonomous Haulage with Powerful FMS Integration in Open-Pit Mines

Ore Blending and Grade Control at ROM Stockpile

ROM Loader: 5 Powerful Reasons Mills Experience Lower Yield and How to Skyrocket Yield and Throughput

Maximizing Blending Compliance: GroundHog Launches Advanced ROM Loader Software

Underground FACE DRILLING SOP

Drilling For Success

Ore Dilution and Quality Control in Open Pit Mines

Improving Operational Efficiency at Mines.

Digital Transformation and Change Management in Mining

Launching GroundHog Maintenance Cloud: Revolutionizing Mining Maintenance for Planners and Reliability Engineers

Achieve Unmatched Results: Boost High Precision Digging Accuracy by Over 80% with GroundHog

Elevating Maintenance Operations

Drilling Revolutionized: 4 Powerful Ways GroundHog is Leading the Charge with High-Precision Solutions

Caterpillar Telemetry Data Extraction: A Powerful Technical Guide – Part 1

How Mines Use GPS for Unstoppable Efficiency: 5 Powerful Benefits

Aurenne Case Study

Empowering Mining Operations with Short Interval Control: 5 Strategies for Greater Success

Short Interval Control: A Powerful Process for Boosting Mining Efficiency

Discover the Best Choice: RTK or GNSS for Optimal Mine Performance

Hazard Training That Empowers Your Team with Jobsite-Specific Safety

5 advantages of using BEVs in Mining

Best Tips to Maximize FMS and Telemetry Data Usage: Supercharge Operator Performance

Unlock 99% Accuracy: RTK High Precision GPS Ensures Perfect Grade Control and Compliance to Mine Design

5 Ways Mine Digitization and Automation Boost Productivity and Safety

5 ways to improve Asset Tracking in Underground Mines using RTLS

Discover OSHA’s Crane Operator Requirements: How you can meet them satisfactorily

Safety Directors Are Using GroundHog LMS. You Should Too.